Product Description

1.Technical Data:

1. Model: SHJ-35

2. Screw diameter: 35.6mm,

3. Screw speed (rpm): 400-600,

4. L/D: 32-60

5. Screw torque: 125/115 (N.M),

6. Power: 15-22 KW,

7. Output: 30-120 kg/h

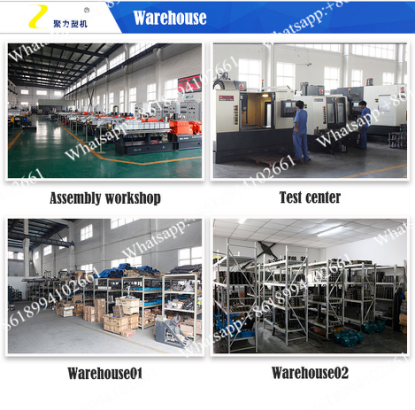

Q1: Are you a factory or trading company?

A: We are factory in Nanjing ,with export license

and we have done export business over 20 years professional.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3: Is your product can be assured ?

A: Our machine passed ISO9001:2001, has CE certificate by SGS, TUV.

Q4:If we show you our layout of factory, can you help to design the whole process line?

A :Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

Q5:If we have samples of new products, can you help to analysis and design the machine?

A:Yes, Our technical department can help to analysis, design and test the new products you offered.

Representative Materials of Co-rotating Twin screw Extruder (Reference Values)

|

Process

|

Representative materials

|

|

Mixing nature changing

|

PE,PP,PS+SBS,PA+EPDM,PP+NBR,EVA +Silicon rubber, etc.

|

|

PE,PA,PC,CPE+ABS(alloy),PBT+PET,PP+ PE etc.

|

|

Filling nature-changing

|

PE,PP,EVA, etc.+ Calcium carbonate, talcum powder, titanic powder

ABS,PC,PS, etc.+ aluminum hydroxide, magnesium hydroxide, antimony oxide.

|

|

PP,PA,ABS +ferrous powder, sulphuric powder ceramic powder

|

|

Functional machine pellets

|

PP,PA,ABS,PBT, etc+ anti-burning agent and other auxiliary agents: combustion-supporting machine pellets

|

|

PE,PP,PS, etc+ starch: de-composing machine pellets

|

|

PE+ fog-preventing dipper, stabilizer: dual-prevention machine pellets

|

|

PE,EVA=ABS etc+ carbon black: black machine pellets

|

|

Colored machine pellets

|

PE,PP,ABS,AS,PA,EVA,PET +pigment and auxiliary

|

|

Intensified glass fibers and carbon fibers

|

PP,PBT,ABS,AS,PA,PC,POM,PPS,PET etc.+ long fibers, small fibers, carbon fibers, crystals and so on, etc.

|

|

Various cables

|

HDPE,LDPE,LLDPE,MDPE,EVA,PVC,PP, etc. insulating cables,coatings,

PE peroxide silicon alkyl crossing cables: radialization crossing cables

|

|

Special materials

|

EVA heat-melting glue, polyurethane, fluorine rubber, fluorine plastics, PP cigarette filtering material and TPR sole material

|

|

Reaction extruding

|

Poly-amide condensate, poly-amide melting polymerization, poly-amide polythene-adding, poly-carbonate condensate, etc.

|

|

Exhausting and volatilization

|

Polystyrene oxide, high-absorbing resin, chlorine sulphur polyethylene

|

|

Powder paint

|

Polyester, ring oxide, lactide, polyurethane, acrylate

|

Q1: Are you a factory or trading company?

A: We are factory in Nanjing ,with export license

and we have done export business over 20 years professional.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3: Is your product can be assured ?

A: Our machine passed ISO9001:2001, has CE certificate by SGS, TUV.

Q4:If we show you our layout of factory, can you help to design the whole process line?

A :Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

Q5:If we have samples of new products, can you help to analysis and design the machine?

A:Yes, Our technical department can help to analysis, design and test the new products you offered.

Commercial Term

Negotiation

· About formula, machine configuration, price (payment term), delivery term, service term

· Lab extruder available for testing

During fabrication

· Machine layout drawing

· Processing status

After-sale

· Installation, debugging and training service

· Long-term technical support

.png) Contact Now

Contact Now