Product Description

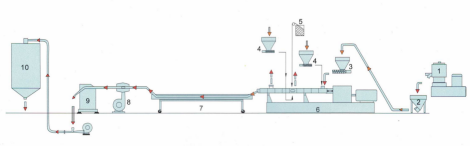

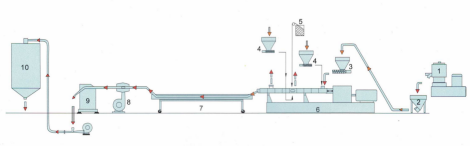

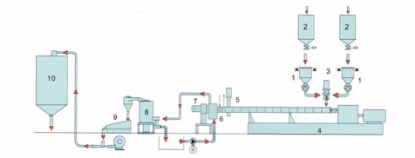

1.Twin screw extruder water-cooling strand pelletizing production line

Applications:

Enforcing modification: PE, EVA etc.+CaCo3 , Talc, TiO2 , Carbon black;

Biodegradable

masterbatch: PE, PS etc. +starch, additive etc; Anti-flame masterbatch:

PE, EVA etc. + Sb2O3 , Mg( OH)2, Al2(OH)3 etc.

3.Twin screw extruder water-ring hot face pelletizing production line

1.High speed mixer 2.Spiral conveyer 3. Main Feeder 4.Side feeder

5.Glass Fiber 6.Twin screw extruder 7. Water trough 8.Air-knife

9.Pelletizer 10.Product container

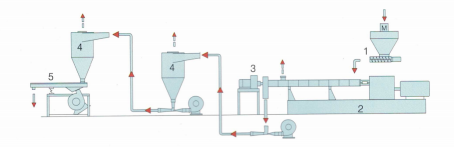

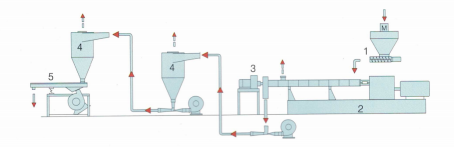

2.Twin screw extruder air-cooling hot face pelletizing production line

1.Metering Feeder 2.Twin screw extruder 3.Air-cooling hot-face pelletizer 4.Cyclone system 5.Vibrating Sieve

Applications:

Enforcing modification: PE, EVA etc.+CaCo3 , Talc, TiO2 , Carbon black;

Biodegradable masterbatch: PE, PS etc. +starch, additive etc; Anti-flame masterbatch: PE, EVA etc. + Sb2O3 , Mg( OH)2, Al2(OH)3 etc.

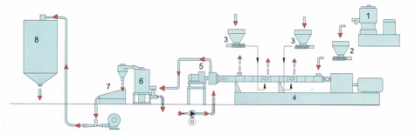

3.Twin screw extruder water-ring hot face pelletizing production line

1.High speed mixer 2. Main Feeder 3. Side feeder 4.Twin screw extruder

5. Water-ring pelletizer 6.Centrifugal dewatering 7.Vibrating Sieve 8.Product container

Application:

PE, EVA etc. Filled with CaCO3, talc, TiO2, carbon black etc. Cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, or MDPE; Radiation-crosslinkable, heat-shrinkable cable compounds; PPR pipe compounds, PE compounds for crosslinked pipes; TPR, TPU, TPV thermoplastic elastomers; EVA and hot-melt adhesives; Color concentrates of PE, ABS, PS, EVA, etc; Flame retardant masterbatches of ABS, EVA etc; Masterbatches with PE, PP, PS etc as carriers for degradation applications.

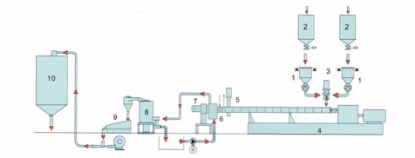

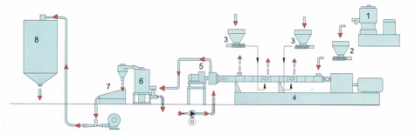

4.Twin screw extruder under water pelletizing production line

1.Loss-in-weight feeder 2.Material silo 3.Forced feeding 4.Twin screw extruder

5.Diverter valve 6.Screen changer 7.Underwater pelletizer 8.Centrifugal dewatering 9.Vibrating Sieve 10.Product container

Application:

PP, PE and its compounds, various of thermoplastic elastomers, PA, TPU, EVA and other hot melt adhesive.

Extensive heat and mass transfer, narrow residence time distribution, large surface to volume ratio, continuous operation. Ideal for high viscosity, high temperature reaction systems.

Continuous polymerization or reactive extrusion like dynamic vulcanization, crosslinking, grafting, and chain extension of PUR, PA, POM, PEI, PC, PMMA, PBT, PPS, etc.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now