- Home

- About Us

-

Products

-

Twin Screw Extruder

- Filler Masterbatch Extruder

- Color Masterbatch Extruder

- Engineering Granules Extruder

- PET Bottles Flakes Recycling Extruder

- White Masterbatch Extruder

- Black Masterbatch Extruder

- Lab Double Screw Extruder

- Thermoplastics Elastomer TPU TPR Extruder

- EVA Heat-melting Glue Extruder

- Reinforced Glass Fibers Extruder

- Single Screw Extruder

- Two Stage Extruder

- Single Screw Two Stage Extruder

- Biodegradable Sheet Extruder

- Biodegradable Pelletizing Extruder

- Sheet Extruder

- WPC Extruder

- Three Screw Extruder

- CHC Energy Saving Extruder

- Air Cooling Belt Conveyor System

- Kneader Extrusion Line

- Stone Paper Machine

- Twin Screw Extruder Feeding System

- Water-cooling Strands Pelletizing

- Underwater Pelletizer

- Water Ring Cutting System

- Die Face Cutting System

- Plastic Mixer

- Extruder Auxiliary Parts

- Related Extruder

-

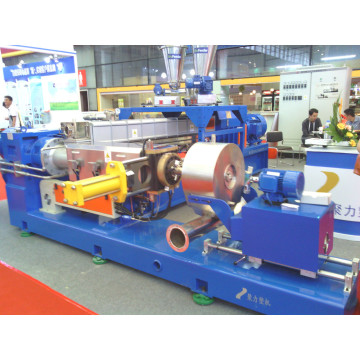

Twin Screw Extruder

- Contact

Contact Now

Contact Now