Product Description

Twin screw extrusion has become the standard over time in several industries because it offers numerous advantages over single screw extrusion:

· More consistency in production and control of product quality

· Increased productivity due to continuous processing, faster start up and shut down between product changes, quick changeover and advanced automation

· Greater flexibility, with the capability to process a wide range of raw materials

· Simple and easy to maintain and clean

1. Application

Masterbatch, Plastics modification, Cable compounds, Powder coating and toners, PE communication cable material, Silane XLPE material etc.

2. Main feature

- Parallel twin screw, co-rotation, modular design, exchangeable -screw design.

- Segmented barrel, exchangeable design.

- New designed gear box and transmission system, high torque, perfect performance.

- Multiform feeder system for specialized process.

- More options for control system, i.e. PLCS, PECS etc.

- Multiform pelletizing system for best solution.

- Easy arrangement, no foundation required.

1.The gearbox

· New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and the torque assignment get together, which keep it compact, and the key bearings are imported.

·The select material of drive components of twin screw extruder machine is dainty, including super intension alloy cementiteing steel, cementiting and quenching, gear grinding technics, strengthening of tooth face. So they can ensure high torque, high precision and low noise.

· Soakage and coerce lubrication integrate smoothly. When the hydraulic circuit is over pressed, it alarms.

2.The feeding system

·The metering feeders of PP/PE twin screw extruder is equipped with single screw, twin screw, hollow screw, forced-feeding, side feeding, liquid-adding system,etc.

3.Screw

·The screw elements and then kneading blocks are designed accurately, by precise processed, agile combination, with interchangeability, which can fulfill efficient self-cleaning, transmission, compounding, pressure-forming. Good combination and design, can make water cut mini twin screw extruders have a multiplier effect.

· The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treatment.

4.The barrel

· Eurostyle rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller.

· According to the material and special technical demands, the material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding process.

5.The heater

·Innovated design of heater tightened style insures high efficiency of heat transfer and high longervity of heater, in order to ensure that PP/PE twin screw extruder can work better for you.

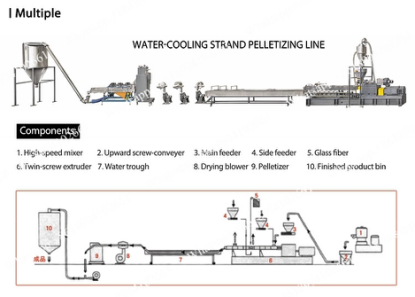

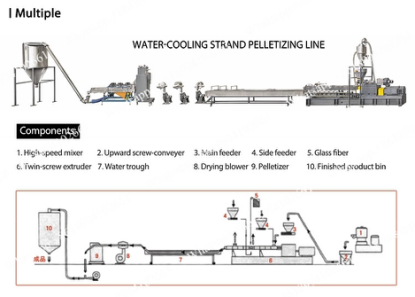

6.Pelletizing

· Various modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelletizing, etc.

Before-sale

1. Introduce products and applications detain

2. Recommend suitable solution

3. Provide with reference in formation

4. Offer lab for test

During manufacturing

1. Provide with layout and engineering conditions

2. Inform the project processing status

3. Offer other documents

After-sale

1. Provide with installation ,commissioning and training

3. Offer spare parts

4. Provide with technical support

5. Visit customer regularly and correct information

.png) Contact Now

Contact Now