Product Description

Horizontal ribbon mixerconsist

shaped barrel, agitator, speed reducer and electric motor .Untwist double ribbon are swirled with the main shaft in the U shape barrel. The outer ribbon push the material from the two ends to the center of the barrel, inner ribbon push the material from center to the two ends.Thus to achieve material convention

Under the driven of motor, the double ribbon agitator mix the material quickly. This ribbon blender is characterized by high mixing effect, large productivity, and a very low failure rate. Since it is a batch type mixer, customer should choose the model according to the output per batch.

The discharging port is set in the bottom center, with the help of the outer ribbon,the material can be discharged completely, and no dead zone.

We also provide suitable feeding machine for the ribbon blender,such as screw conveyor,vacuum conveyor,bucket elevator,flexible screw conveyor etc.

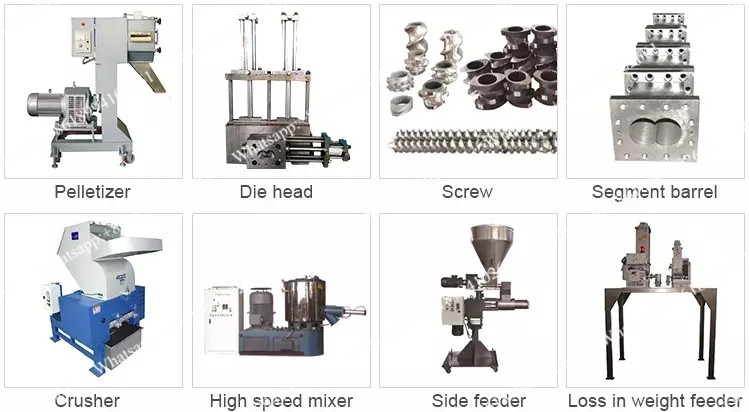

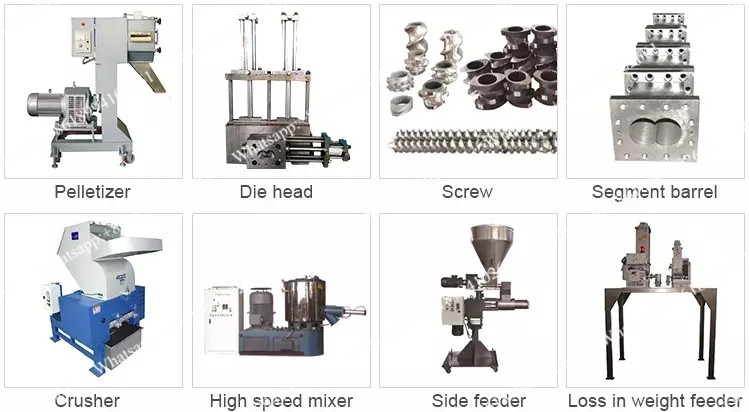

Additional configuration:

1. Driven unit: Many worldwide famous brands are for option: SEW, ABB, Siemens and so on

2. Bearings: NSK/SKF and so on

3. Heating/cooling jacket

4. Spraying system

5. Heavy duty type ( loading your material into the mixer first and then start the mixer)

6. Platform: we build the platform for you or we design it and you build it locally

7. Mixing system: including packing machine, bucket elevator, Sieve, screw conveyor and so.

Customizing according to client’s specific requirement

Application:

The horizontal ribbon mixer is widely used in chemical, pharmaceuticals, food, and construction line. It can be used to mix powder with powder, powder with liquid, and powder with granule.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now