Product Description

Application

Vertical color mixer is for mixing powder and granular materials. It is mainly used in mixing plastics industry and is also widely used in mixing materials used in industries such as powder, metallurgy, ceramics and etc. It has a simple structure, easy to operate, easy to maintain and clean, fast and excellent performance in mixing materials.

It also can be customized based on your requirement for food & grain grade mixing.

Features of Color Mixing Machine

1. Mixing blades and barrels are made of stainless steel, thick & solid and durable.

2. Interface polished smooth, easy and quick cleaning.

3. Mixing blades is removable for easy cleaning and maintenance.

4. Sealed mixing, no leakage of material.

5. Vertical type for easy operation and with small footprint.

6. 3~5 minutes to mix completely, low energy consumption and high effiency.

7. Time setting can be controlled easily and Precisely in the range of 0 - 30minutes.

8. Interlock protection device to ensure the safety for the operator.

9. With a larger size (300Kg-1000Kg) available for customers to choose.

Operation

First, inspection:

1, check whether the stirring blades are loose, lubrication is good.

2, the opening idling, check the abnormal noise and other abnormal conditions, to confirm that everything is normal before the boot work.

3, check the mixing cylinder has no foreign bodies, whether clean.

4, check whether the safety switch is flexible and effective.

Second, safe operation:

1, the various materials according to the process requirements of the formula measures and quantities to add to the mixer.

2, the lid can be covered before starting the motor, and according to the specified time to stir.

3, the operation of the process is strictly prohibited to reach into the mixer grip, if you want to see, you should first stop.

4, if you need to clean up the machine, you should first cut off the power supply, before you can operate.

Third, shutdown operation:

1.after the shutdown should be shut down the machine power supply, shut down the leakage switch, cut off the power supply can be off the post.

2. after the shutdown, the equipment should be thoroughly wiped clean, especially the rotating parts of each other, strictly prohibited dust accumulation.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

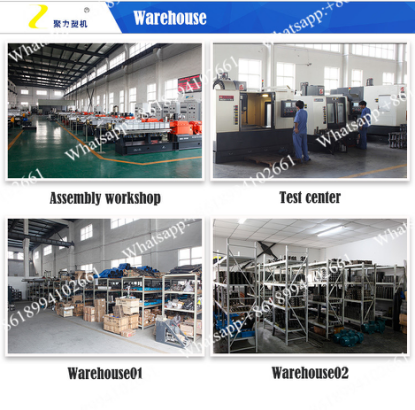

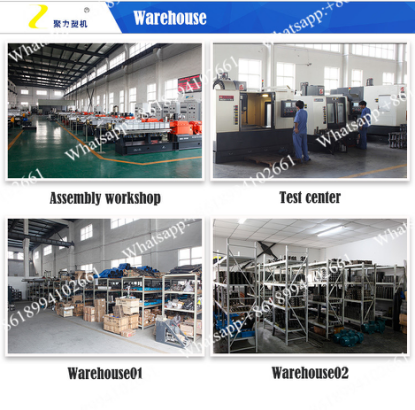

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now