Product Description

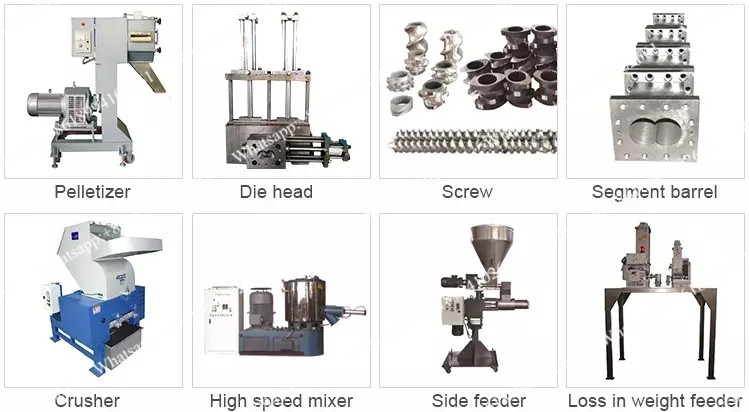

The suitable high speed mixer can help you a lot in your production. The high speed mixer is used in mixing, stiring , drying, coloring so the high speed mixer plays a huge role in the other processing of all kinds of materials in plastics, rubber, daily chemical and other industries. Because of this ,the quality of the high speed mixer is very important. As a manufacturer of the high speed mixer, our goal is to be the best high speed mixer manufacturer. So we are very value the quality of the high speed mixer .If you use our high speed mixer, you won’t feel disappointed and the high speed mixer won’t make you any trouble. If you want to know more about the high speed mixer, please contact us.

Features:

It is used in mixing, stirring, drying, coloring and other processing of all kinds of materials in plastics, rubber, daily chemical and other industries.

The technology of sealing main shaft is given the state patent.

The technique of two layers of sealing is adopted in its pot cover. It has self-friction heating and electric heating modes.

The discharging mode is temperature-automatic control and manual control.

High speed Mixer Machine and Cooling Mixer Machine Unit

1. High speed Mixer Machine and Cooling Mixer Machine Unit is applicable for mixing, coloring and drying of various resin, such as polyethylene, polypropylene, polyvinyl chloride, etc. and in the craft of engineering plastics such as ABS, polycarbonate etc. before forming and processing as well as in the mixing of phenolic resin.

2. High speed mixer and cooling mixer unit combines heat mixing and cooling mixing craft together. the materials after heat mixing can be conveyed to cool mixer for cooling automatically, exhaust remaining gases and prevent agglomeration.

3. High speed mixer and cooling mixer unit model by adopting PLC control, it features high automatic level, and good mixing result.

4. High speed mixer and cooling mixer unit paddles have passed the test of dynamic and static equilibrium. the lid adopts double concave-convex seal. Main axis seal adopts special tech of our company, also equipped with pulse dust catching device.

5. High speed mixer and cooling mixer unit absorbed slowdown tech from overseas, adopts direct slowdown device, overcomes the deadly weakness causing by use of retarder, so features even more smoothly.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now