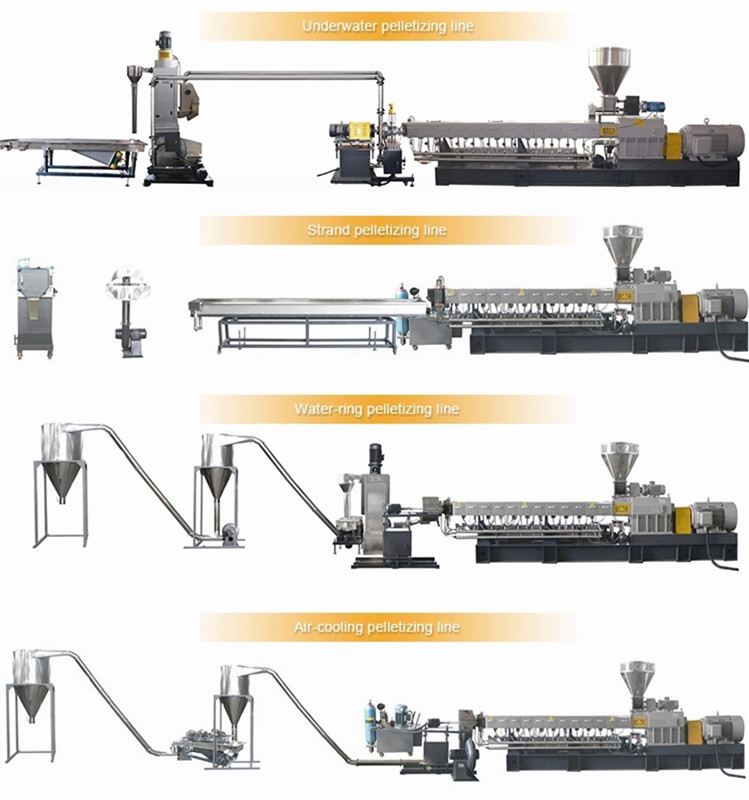

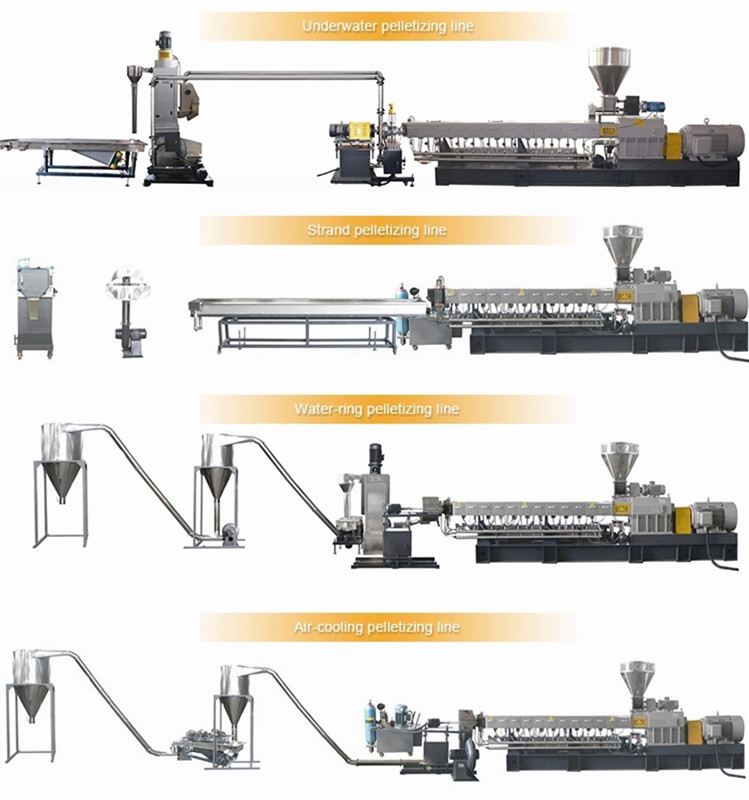

Plastic PET Flakes Pelletizing Line Description :

This pet flakes pelletizing line uses SHJ series parallel twin screw extruder, is suitable for producing PET granules from clean PET flakes.This machine is composed by SHJ parallel twin screw extruder, die, hydraulic screen exchanger,plastic strand die head, water cooling tank, cutter, silo.

This machine is mainly used in PET, PVC and other high viscosity materials. with good performance, high output, less power consumption cost per kilogram, and easy operation.

The machine can reduce less loss of the viscosity of the raw material.

Plastic PET Flakes Pelletizing Line System Configuration:

Processing capacity is 100-800kg/h

The whole include

1.Feeding Machine.

2.Extruder:38CrMoAlA with nitriding processing

3.Mould:40Cr with nitriding processing.

4.Water Channel

5.Winds drying machine

6.Pelletizer machine

7.Hopper

Plastic PET Flakes Pelletizing Line Advantages :

1. Increasing the operation variables and realizing the process because of two-stage machine.

2. High effective and production capacity.

3. Good at process heat-sensitive material and devolatilization operation, Such as PVC, XLPE.

4. Zero halogen cable, shield material, carbon black etc.

.png) Contact Now

Contact Now