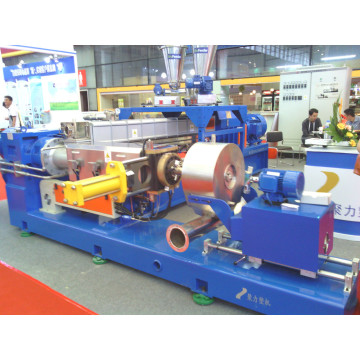

Product Description

A brife introduction of the extruder

Usually the twin screw extruder runs at a high speed for good mixing and high output capacity.

The second extruder must be a larger diameter single screw one that can run at lower screw speed.

The lower screw can avoid speed over-shearing and over-heating by internal cooling system and strong heat exchange ability. The functional separation allows operator to more flexibly control the expectable material mixing process and temperature.

1. Electric control system of twin screw extruder

Frame structure control cabinet

Imported electrical elements

Imported temperature control system

Imported driving system

Interlock and multi-protection

Adopting imported PLC (OMRON or SIMES ) to achieve optimized process control.Stronger function, steady performance and much higher accuracy.

It can be also accomplished full-set link-lock protection,trouble safeguard, fault alarm cluing and so on

Operation interface on touching screen is visual and marked, which is brief and easy to use.

2.The Gearbox

New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and the torque assignment get together, which keep it compact ,and the key bearings are imported.

The select material of drive components is dainty. Including super intension alloy cementiteing steel, cementiting and quenching ,gear grinding technics ,strengthening of tooth face. So they can ensure high torque, high precision and low noise.

Soakage and coerce lubrication integrate smoothly. When the hydraulic circuit is over pressed

3.The compounding system

Euro-style rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller

According to the material and special techinics demands, the material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding process

The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now