♣The main machine line used toy bricks design. We can make adjustment of the L/D,screw configuration

barrelssetup,numbers of feeders and venting,screen changing and way of granulating,even the electric

control systemaccording to different raw material and technical requirement. This design is not only for

specific products,but also fora wider application.

♣ The basic screw elements is full engagement conjugate, designed by CAD, can self-cleaning capacity

andinterchangeability. Based on 20 years experience, we perfect the twin screw extruders performance.

We develop allkinds of screw elements and different configuration to suit the latest plastic raw material and new technology.

♣The connection of screw elements and core axis used the international involute spline form, full explore

the potentialof limited structural space, to achieve the higher torque and bigger screw working volume.

♣To meet different process requirements and applications, based on conventional type A(n<500r/min T/A3 <6)

and highspeed type B(n>600r/min T/A3 <6), recently we make high torque type C(n<500r/min T/A3 <8) and high

speed&hightorque type D(n>600r/min T/A3 >8) gearbox.

♣ The latest torque distribution system,high-precision grinding process, imported bearings and protection of

interlockinglubrication system,to make all products perfect and reliable.All kinds of measuring feeding system

♣can work for different kinds of materials.Besides the standard volumetric meter-ing feeders, the loss-in-weight

feeders with accuracy as 0.5% are also available.

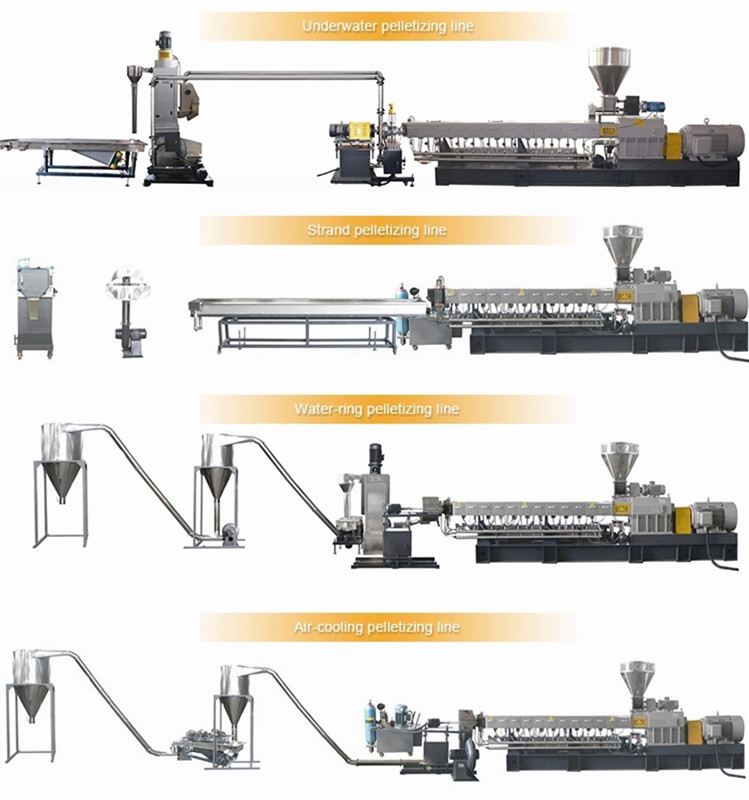

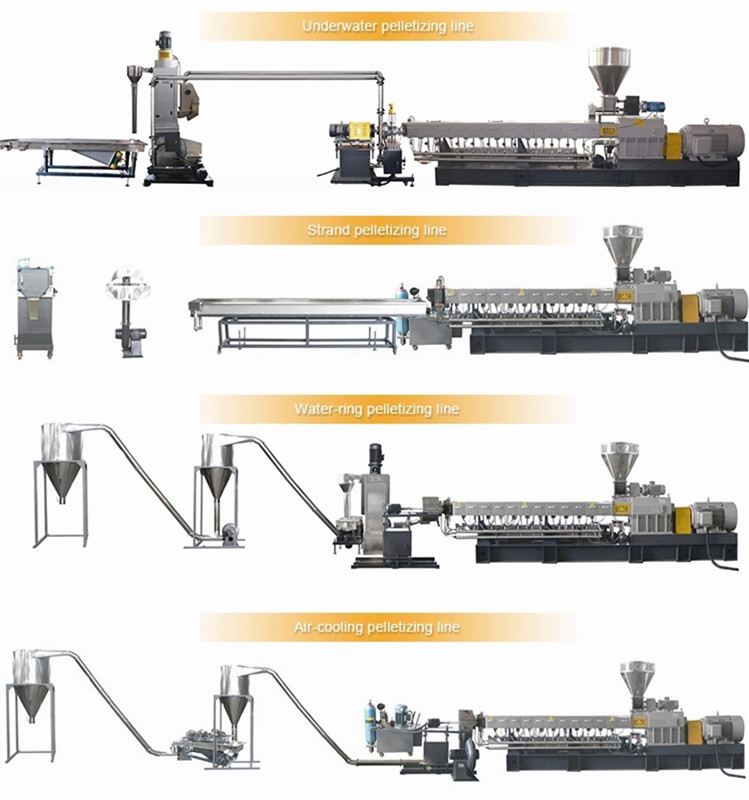

♣Granulating series includes water cooling bracing pelletizing line, air-cooling hot cutting pelletizing lines,

water ring andunderwater pelletizing lines.

♣The main machine material is high speed tool steel with vacuum hardening,can competent most of working request.

Forspecial situation,can choose corrosion resistance and wear resistance treatment.The key components in the

electric control system are imported.Simulating operating panel, PLC or PCC control areprovided upon request

besides the instrument panel.Low vibration and low noise,easy assembling,convenient to use.

.png) Contact Now

Contact Now