Product Description

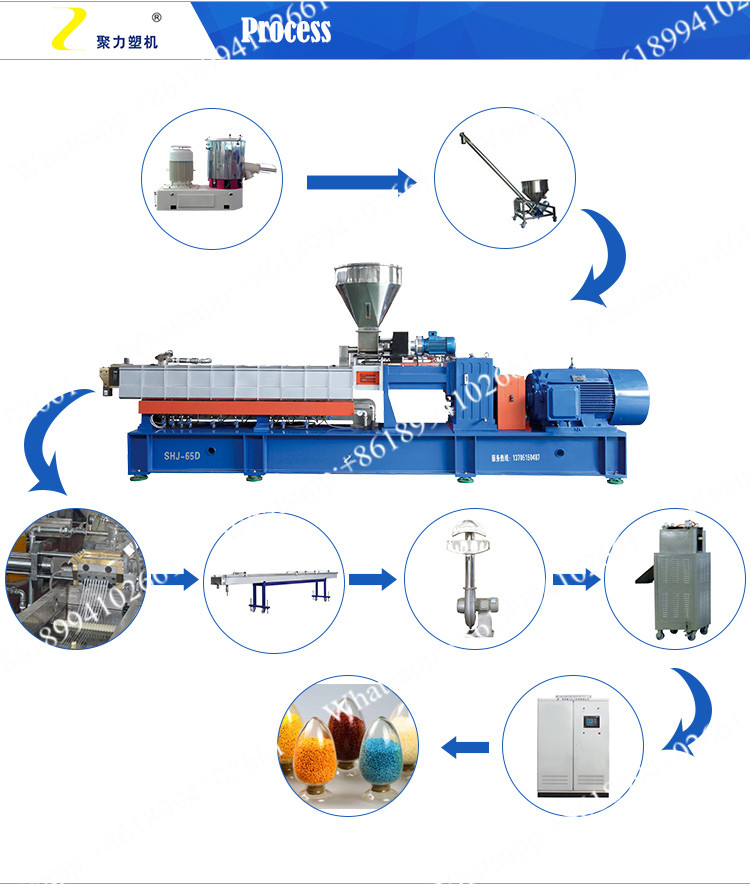

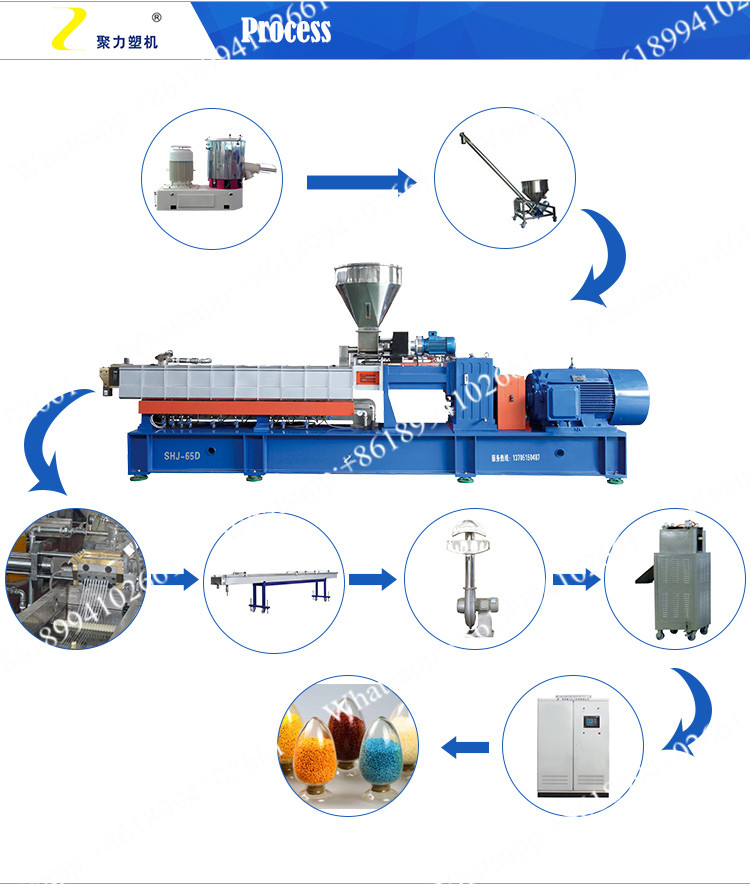

Plastic granules hot-cutting pelletizing line:

1. Plastic Pelletizing Line is composed of twin screw extruder and corresponding auxiliary machinery.

2. The produced pellets are uniform and dense.

3. The auxiliary machinery adopt die surface pelletizing,wind conveying and cooling system with high automation,precise cutting,efficient output and other characteristics.

4. PVC compounders are widely used in Cable, Pipe Producing, Medical Hose, WPC Pelletiizng field,etc.

|

Product name

|

100% biodegradable granule making machine

|

|

Processing

|

materialPLA/PBAT/PVA+Corn starch/Cassava starch+some small additivesFinal product100% biodegradable granule

|

|

Application

|

Films, bags, plates, cups, straws, chopsticks,etc

|

|

Capacity

|

10~1000KG/H (We can provide any capacity model as per cutomers' need)

|

|

Certification

|

CE&ISO

|

|

Formula

|

Available (We have formulation, it can be provide to customers together with the machine)

|

|

Project

|

Turn-key project

|

SHJ Co-rotating Parallel Twin-Screw Extruder Features

1. Screw components designed by computer aids is kneading type, has excellent self-cleaning function, the new kneading block design effectively avoid the problems of overheating and energy consumption.

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array, venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling Die Face hot cutting, water ring die face hot cutting, Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

4. Application: Filling Modification, glass fiber (carbon fiber) enhance various kinds of master batch, rubber and plastics compounding, plastic alloys, functional master batch, Various kinds of electric cable material, reactive extrusion. Devolatilization process, powder coating and so on..

Pre-sales service

♦1.Introducing in detail features and application of the products to customer.

♦2.Selecting economical and practical machine & equipment for customer.

♦3.Providing operation data of the related machine & equipment.

♦4.Providing means of trial performance for customer.

After-sales service

♦1.Providing on-the-spot technical assistance in installation ,commissioning and training.

♦2.Filing in detail customer’s information.

♦3.Providing long-term maintenance service and spare parts.

♦4.Giving technical support to customer for developing new product.

♦5.Providing free maintenance for a year.

.png) Contact Now

Contact Now