Product Description

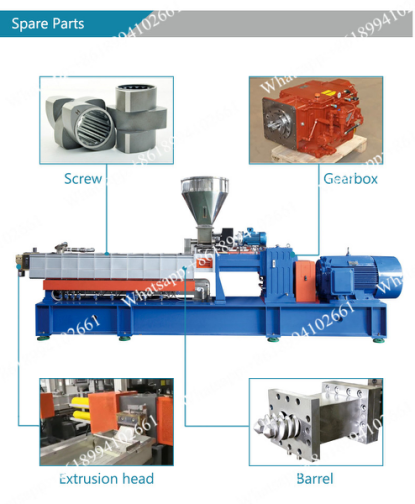

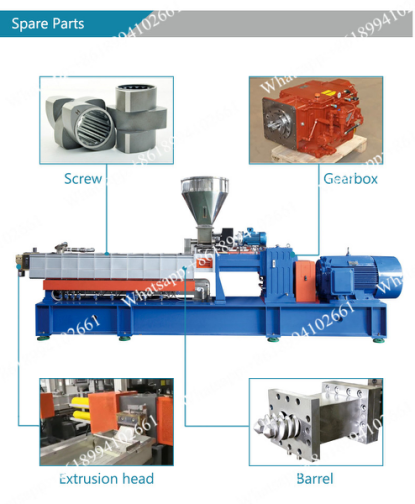

The screw diameter Φ62.4 mm, L/D=40 1, designed using by toy bricks principle.

The material of screw core axle is 40 CrNiMoA,

the material of screw element adopted high speed tool steel:

6WMO5Cr4V2, with high temperature vacuum quenching heat treatment.

The screw element and core axle is connected by involute structure with bearing large workload, make up easily, after heat-treatment, the hardness of it can reach HRC 58-64.

1. Technical data :

|

Type

|

Series

|

D(mm)

|

L/D

|

n(r/min)

|

P(kw)

|

T(N.m)

|

T/A³

|

Q(kg/h)

|

|

SHJ-65

|

A

|

62.4

|

32-60

|

500

|

75

|

680

|

4.8

|

200~355

|

|

B

|

600

|

90

|

680

|

4.8

|

255~400

|

|

C

|

600

|

110

|

830

|

5.9

|

300~550

|

|

D

|

600

|

160

|

1200

|

8.5

|

500~850

|

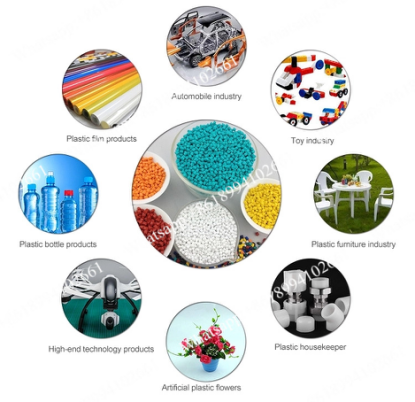

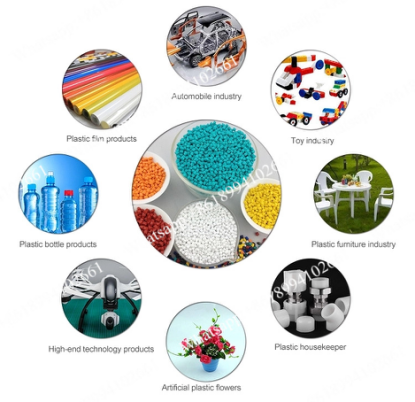

Application for water-cooling strand

1. Fiber reinforcement and modification: filling glass fiber or carbon fiber for: PP, PA, PBT, ABS, AS, POM, PPS, PET, etc

2. Ploymer compounding: PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+EPDM,

PA+SBS, etc.

3. Filling modified: Filling CaCO3,Talc,Titanium, carbon black for PVC PE,PP, EVA etc.

4. Cable material: cable sheath, cable insulation compounds,crosslinking compounds, optical fiber protection compounds, cable coating material, thermal contraction material,etc.

5. Dedicated material: PPR pipe compounds, PE crosslinking tube material, cigarettes filter tip material, acetate fiber material, etc.

6. High Concentration Color Masterbatch: PE,ABS,PS,EVA,PET,PP + color +

additives, etc.

7. Flaming Retardants: PVC, PP, PA, ABS, EVA, PBT + flame retardants, etc.

8. Special Functional Masterbatch: double protection masterbatch, antistatic masterbatch, anti-bacteria masterbatch, thermal insulation masterbatch, hypothermia material, etc.

9. The degradable masterbatch: PP, PE, PS + starch+ additives, etc.

FAQ

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

Q6: Why choose you ?

A: 1) Quick response. Once we got the inquiries from you, we will reply you within 12hours.

2) Promising leading time. To guarantee the quality, the machine will be finished within max 20days.

3) Before leaving factory, all the machine will be fully tested.

4) Customized package(Wooden) will ensure a safety shipping.

.png) Contact Now

Contact Now