Product Description

CaCo3 filler masterbatch machine/PP PE masterbatch extruder

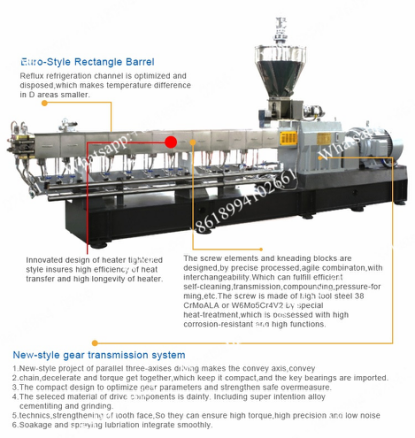

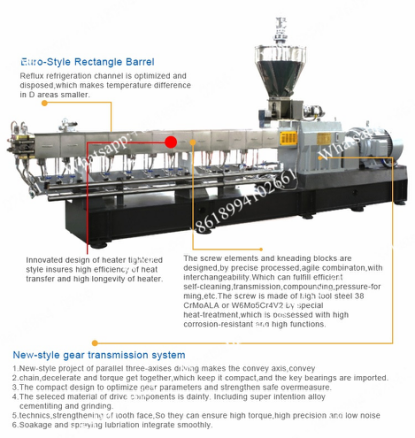

Wind cooling twin screw extruder is belong to High Torque Co-rotating Twin-screw Extruder. This parallel co-rotating twin screw extruders have excellent mixing performance,good self-cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material.

Application field:

Filling modification

CaCo3

Talcum powder

Barium sulfate

Titanium pigment

Ceramic powder

Wood flour/plant fiber

Other inorganic filler

Reinforce modification

Short glass fiber

Long glass fiber

Carbon fiber

Other whisker

Preparation of master batch

Carbon black master-batch

Color master batch

Flame-retardant master-batch

Degradation master-batch

Other special functions master-batch

Blending modification

Thermoplastic material/TPE

Polymer alloys

Cable material

PVC cable material

Zero halogen cable material

PE TR-XLPE,NDH

PE cross-linking cable material

Special cable material

The advantage of plastic granulator:

1. High output

2. Main parts (reducer, motor, inverter) use domestic well-known brand, quality have assurance, equipment with long life and good performance.

3. Delicate appearance, Nice surface treatment .

4. Competitive price afford high quality equiment with fast delivery

Applications of Twin Screw Extruder Machine:

· (1) Biodegradable material: PE/PLA/PBAT+starch/additives etc.;

· (2) Thick masterbatch:PE, ABS, PS, PP+ pigment, additives;

· (3) Flame retardant masterbatch: PP, PA, ABS+ flame retardant, additives, etc.;

· (4) Filling modification: PE/EVA+ calcium carbonate, talc powder,TiO2,carbon black, etc.;

· (5) Enhanced modification:PP,PA,PBT, ABS, AS, PC, POM, PPS, PET +glass fiber, carbon fiber;

· (6) Blending alloy: PC+ABS, PA+ABS, CPE+ABS, PP+EPDM, PA+EPDM, PP+SBS etc.;

· (7) Cable material: PVC、PE、low smoke and halogen free etc.;

· (8) Engineering plastics: ABS、PEEK、PC etc.;

· (9) Thermoplastic elastomer:TPU、TPE etc.;

· (10) Color masterbatch: PE, ABS, PS, EVA, PET, PP+pigment, auxiliaries;

(11) Flame retardant color mother: PP, PA, ABS, EVA, PBT+flame retardant.

.png) Contact Now

Contact Now