Product Description

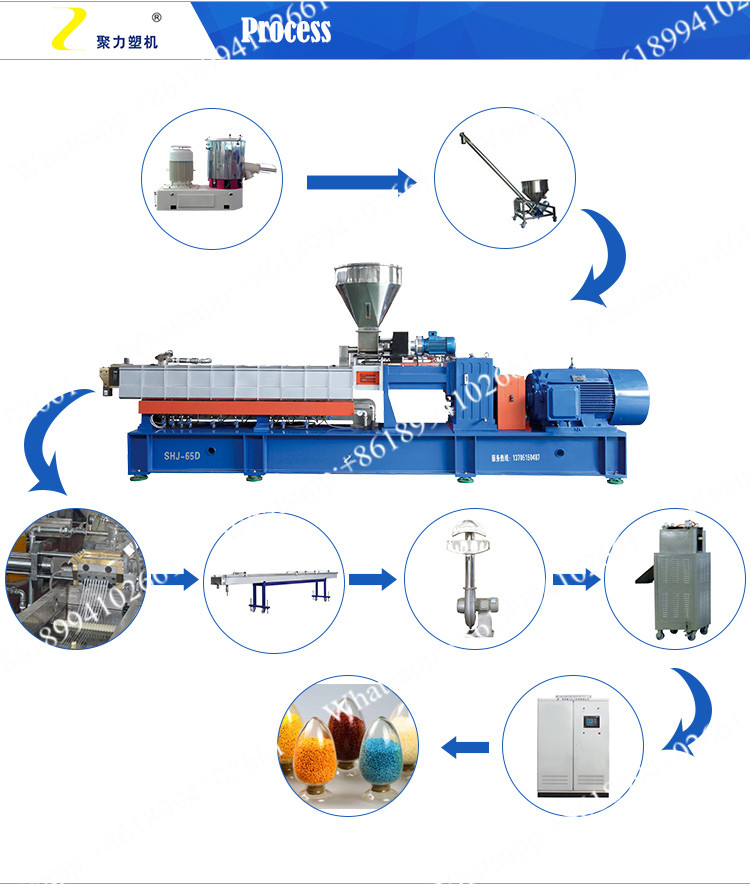

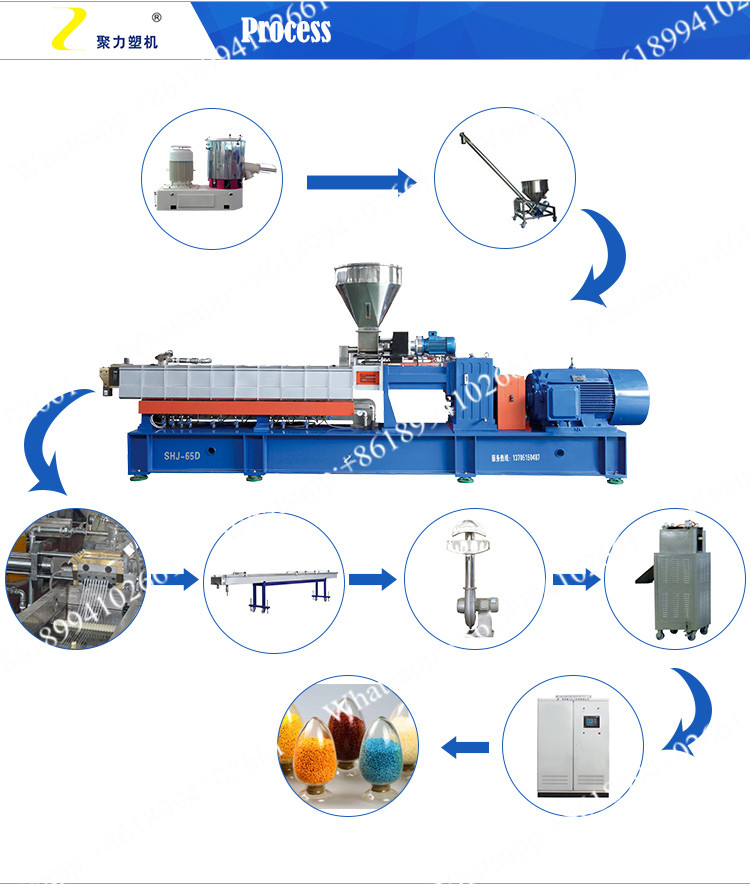

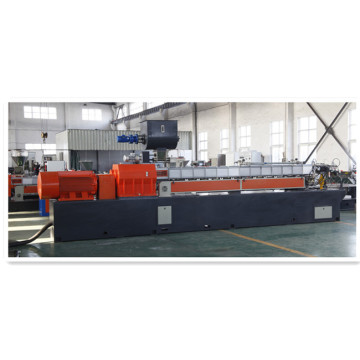

Calcium carbonate filler masterbatch extruder machine with kneader single screw extruder introduction:

--- It has good mixing and dispersion performance.

--- The max filling percentage can be 92%.

--- The pelletizing system can be chose, mainly used for extrusion of soft, hard polyvinyl chloride polyethlene and other thermoplastics with it, and the corresponding auxiliary(including molding machine), processing avarietyof plastic products, such as pipe,plate,wire.etc, also can be used.

--- This machine has advanced design, high yield, good plastification, low energy consumption, the use of involute gear transmissionand has the advantages of low noise, stable operation, load bearing force, long life characteristics.

Twin Screw Co-rotating Extruder Advantages

1. simple process

2. automatic temperature control

3. low power consumption

4. non-pollution

5. high capacity

FAQ

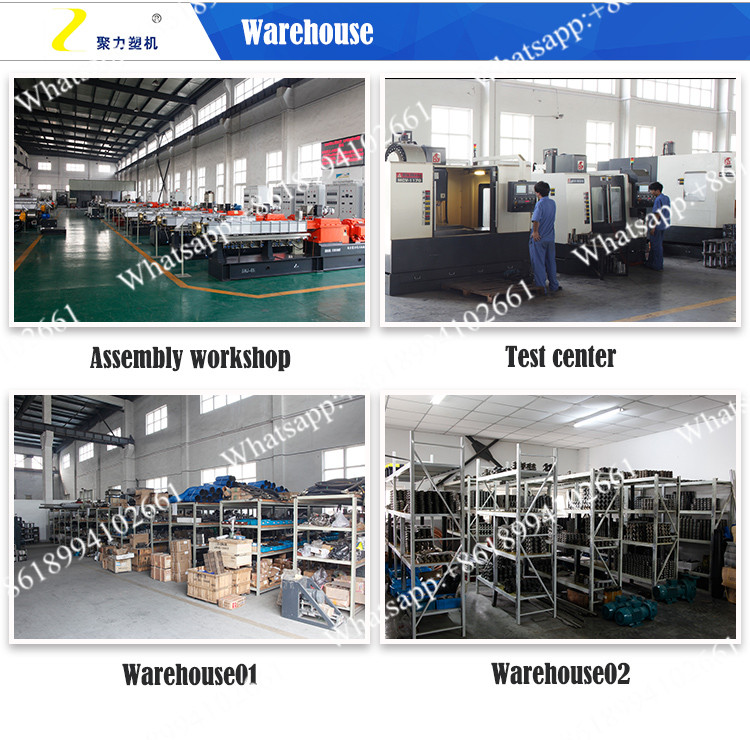

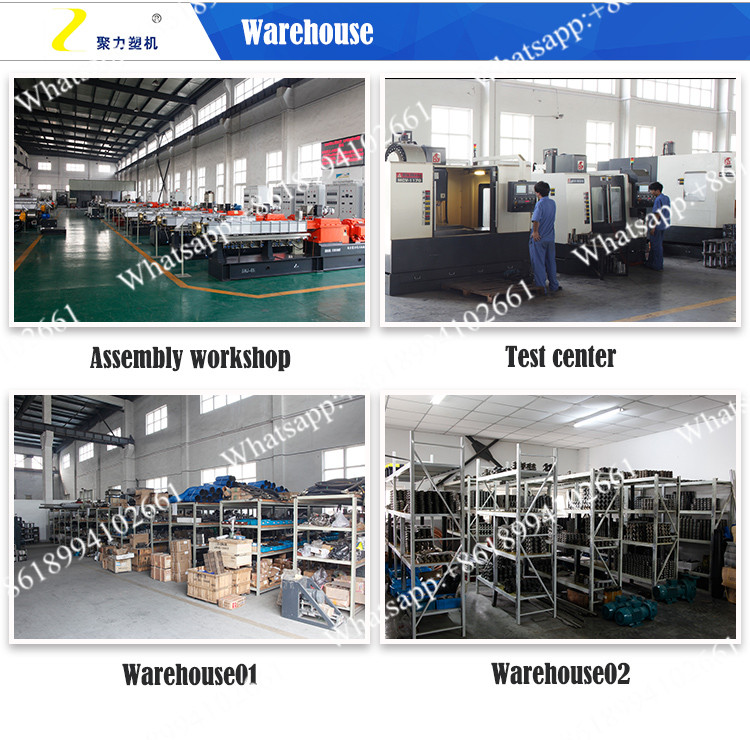

Q1: Are you a factory or trading company ? How is you factory extrusion experience?

A: We are factory in Nanjing , 20 years experience on extrusion.Leading supplier in Nanjing city.

Q2:Where is your factory located? How can I visit there?

A : Our factory is based in 77 Tangtong Rd,Hushu,Jiangning District Nanjing , Jiangsu Province, China,

1) You can fly to Nanjing Lukou Airport or you can fly to Shanghai then take high-speed train to Nanjing South Railway Station.

2) We will arrange the pick up in Nanjing Lukou airport or South Railway Station

Q3:What can you provide for after sale service?

A:We can send engineers to your factory for installation and training if customers‘ required

Q4:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q5:Could you afford technician team to guide ours installation and commissioning?

A:Experience engineer oversea installation service provided.

.png) Contact Now

Contact Now